Home / Products /

Thin and Thick Film Coatings on Flexible Substrates

Thin and Thick Film Coatings on Flexible Substrates

CUSTOM THIN FILM COATED FLEXIBLE SUBSTRATES

Dontech is a custom designer and manufacturer of thin film coatings on flexible substrates. Dontech designs and applies custom thin film coatings on sheets and rolls of flexible substrates. We can thin film coat one or both sides of almost any flexible substrates including acrylic, triacetate (TAC) or cellulose triacetate, cyclo olefin polymers (COP), fluoropolymers, glass, polycarbonate, polyethylene terephthalate (PET), and polyimides. Coatings can be a single layer to multilayer (e.g., 100+) in design.

Dontech is a custom designer and manufacturer of thin film coatings on flexible substrates. Dontech designs and applies custom thin film coatings on sheets and rolls of flexible substrates. We can thin film coat one or both sides of almost any flexible substrates including acrylic, triacetate (TAC) or cellulose triacetate, cyclo olefin polymers (COP), fluoropolymers, glass, polycarbonate, polyethylene terephthalate (PET), and polyimides. Coatings can be a single layer to multilayer (e.g., 100+) in design.

Substrates are coated in various width formats on roll-to-roll (R2R) and batch coating systems to add performance enhancing properties to the substrate (e.g., improve optical, electrical, and environmental properties). Coatings can be applied over thick film hard coatings. Our state-of-the-art in-house thin film R2R and batch coating systems include AC and DC magnetron sputtering, ion-enhanced E-beam evaporation, and chemical vapor deposition (CVD) systems. Custom coatings are subject to setup charges and minimum runs.

STANDARD OPTICAL COATINGS ON FLEXIBLE SUBSTRATES

We manufacture a range of standard high-performance coatings on optical grades of polyethylene terephthalate (PET) substrates. These can be purchased in rolls, sheets, and custom-cut pieces. These products are used by our customers to shield electromagnetic noise in optical apertures, create the electrically active optical area for touchscreens, build transparent heaters, control first surface reflections on displays, improve the durability of displays, touchscreens, and keypads, control the transfer of bacteria and viruses from high touch optical apertures, and to passively help keep heat from passing through optical apertures. These common film product families are as follows:

- OCF™ brand transparent conductive films & and legacy VCF™ transparent conductive films

- VARGard™ brand antireflective films

- AMF™ brand antimicrobial films

- HeatShield™ brand solar and heat reflecting films

- MATTEGard™ brand and hard coated films.

Product Portfolio

OCF & VCF Series™ Transparent Conductive Films

Transparent conductive coatings on optical films for EMI/RFI shielding, transparent heating and active optical touchscreen components. Available in rolls, sheets and converted parts.

VARGard™ Reflection Reducing Films

Antireflective (AR) and antireflective / antiglare (AR/AG) coatings on hardcoated PET with an optical PSA on the rear for first surface reflection control. Available in rolls, sheets and converted parts.

AMF™ Antimicrobial Films

Antimicrobial antiglare hardcoatings on PET films with an optical PSA on the rear. Used to control the transfer of bacteria and viruses on high touch optical apertures.

Heat Shield™ IR Reflecting Films

IR-reflecting and visually transmitting thin film coated PET films with optical PSA for passive thermal management of windows and displays. Available in rolls, sheets and converted parts.

MATTEGard™ Hard Coated Plastic Films

Abrasion and chemical resistant thick film with optional antiglare hardcoatings on PET with optical PSA on the rear. Used to improve the durability of displays, touchscreens, and membrane keypads.

Formats and Film Conversion

Dontech’s converting services can be tailored to customer specifications. We slit a variety of materials to customer widths, lengths, and roll sizes. More complex shapes can be converted with laser or die cutting. Protective masks can be applied to the front and rear surfaces of the film.

Coating Equipment

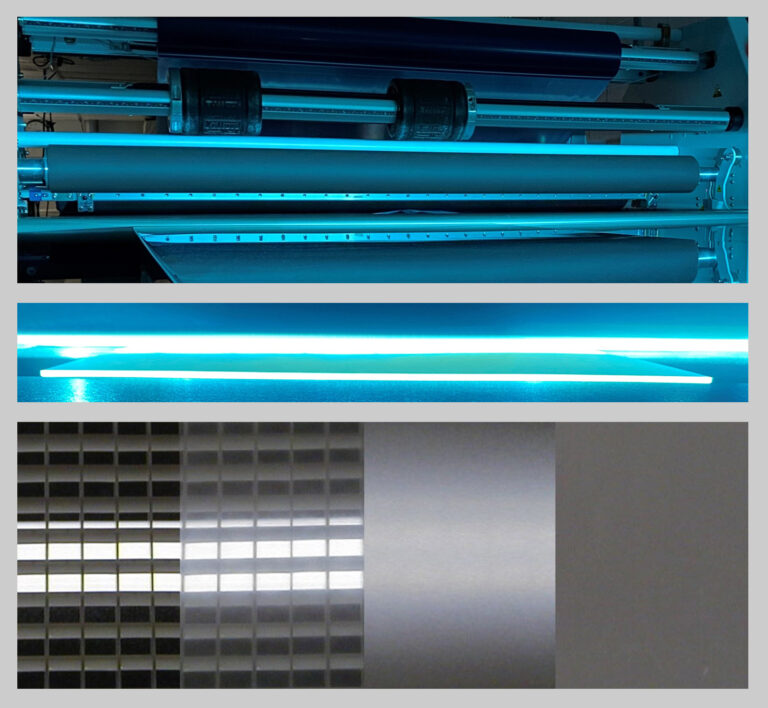

Thick Film Hard Coating Equipment

Thick film coatings include chemical and abrasion resistant hard coatings, hydrophilic (antifog) hard coatings, and diffusion antireflection hard coatings, which are commonly called antiglare coatings. See thick film optical coatings for more details on Dontech’s thick film coating technologies.

Hard coatings improve environmental durability, including chemical, scratch and abrasion resistance. Diffusion antireflective coatings (i.e., antiglare coatings) control surface reflections by scattering or diffusing the specular or mirror reflections on plastic optical substrates. MATTEGard™ and AMF™ Antimicrobial are thick film hard coatings and in the case of the AMF™ formulation it also has antimicrobial properties. Both products are available with diffusion antireflective or antiglare (AG) properties which control surface reflections by scattering or diffusing the specular or mirror reflections from the plastic film. MATTEGard™ is also available without AG properties as a smooth or polished hard surface.

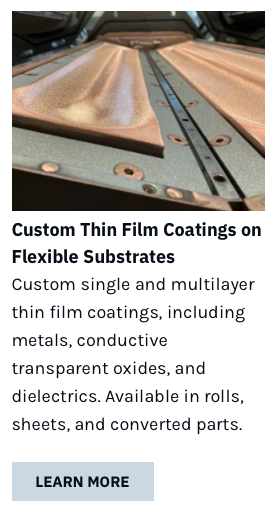

Thin Film Coating Equipment

Dontech has a broad range of thin film coating equipment that can process sheets and rolls of flexible films. We have R2R and batch coating systems including AC and DC magnetron sputtering, ion-enhanced E-beam evaporation, and chemical vapor deposition (CVD). Dontech has extended optical CAD and metrology capabilities, allowing us to perform rapid product development to control our production quality, and to verify the performance of our products. Our equipment can coat an extremely broad range of substrates

We can enhance materials in narrow and wide format R2R and in sheets via batch coating systems, to improve optical, electrical, and environmental properties. For plastic substrates, thin film coatings can be applied over thick film hard coatings or directly to the substrates.

DONTECH & Thin and Thick Film Coatings on Flexible Substrates

Dontech has extensive engineering and technical support resources that can assist you with your flexible substrate design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery.