Home / Products /

Optical Mesh & Plated Mesh Sheets

Optical Mesh & Plated Mesh Sheets

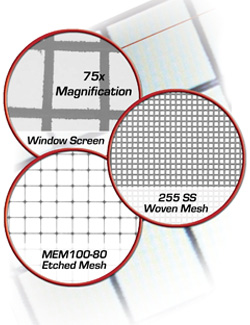

Dontech manufactures an extensive range of conductive optical grids. In addition to patterned and etched conductive coatings which Dontech applies to substrates, we also produce optical fine wire (OFW) woven mesh products with and without performance enhancing platings that in addition to being integrated into optics are also sold as a standalone product.

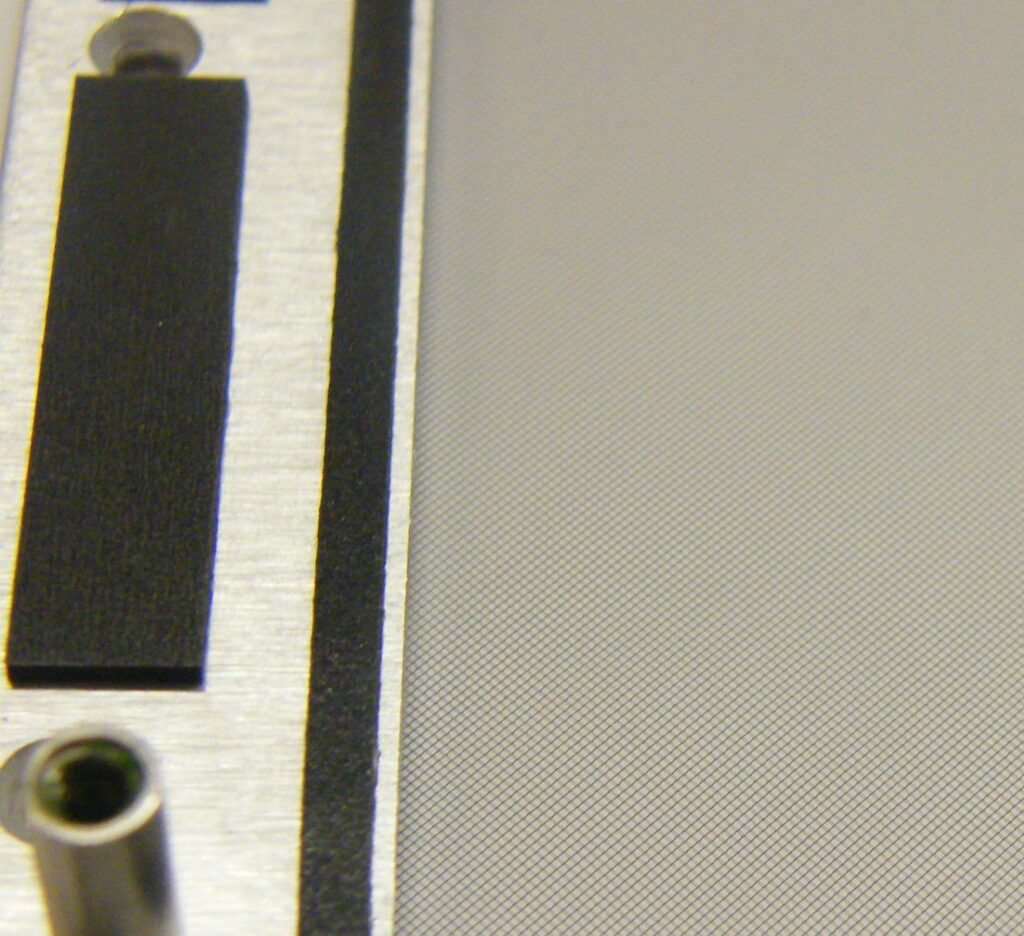

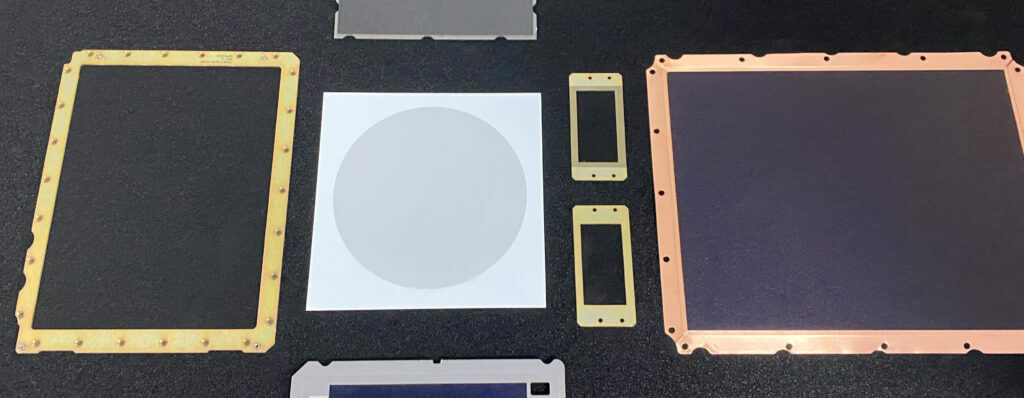

OFW mesh is sold in rolls (unplated versions only), sheets, die cut/laser cut to size, or racked (mounted on a frame). These products are commonly used for the optical EMI/RFI shielding of electronic displays, touchscreens, instrumentation, enclosures, and precision optics.

Product Overview

Performance Enhancing Design Elements

Dontech offers an extensive range of woven optical fine wire meshes sold in standalone sheets and rolls for a wide range of applications. Dontech also has etched or patterned conductive coatings that are available on substrates. Custom sized sheets are available in orientations from 0° to 45° in base mesh and in electroplated formats. Plating is commonly used to improve the OFW’s optical, electrical, and environmental properties. Rolls of OFW are in a parallel orientation and are not plated. The most common application for OFW mesh is for optical EMI/RFI shielding.

Custom Weave Capabilities

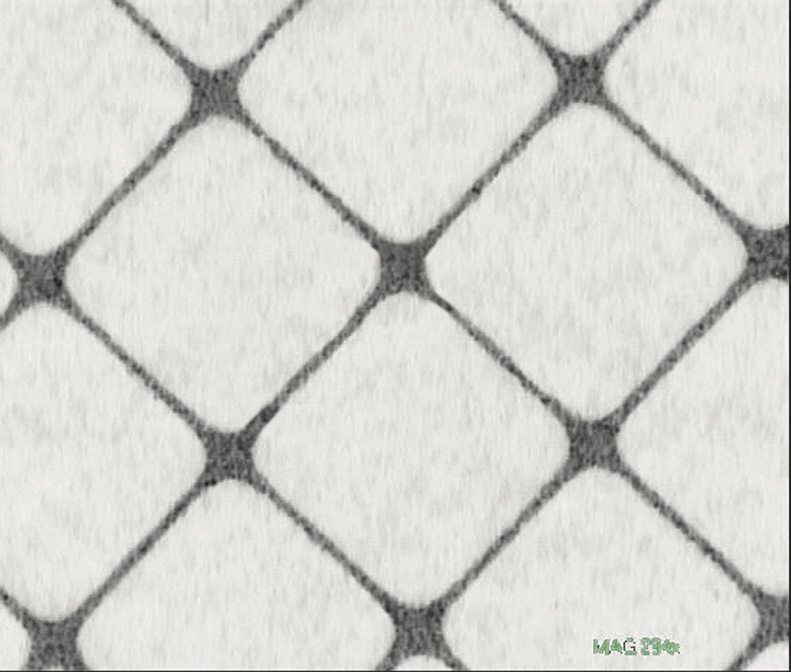

Any material that can be drawn into a wire strand can also be woven into a plain weave mesh form. Plain weave mesh consists of wires crossing alternately over and then under one another as well as having adjacent wires 180° out of phase. The mesh is typically specified by the number of strands per inch in the x and y directions (e.g., 100 x 100 mesh) which is exactly 1 higher than the number of apertures per inch. If the mesh is woven in a square format the number of strands per inch is commonly only stated only once (e.g., 100 mesh). Custom weaves are available in non-square/rectangular formats (i.e., different number of wires per inch in the x direction than the y direction – e.g., 80 x 60 mesh).

Any material that can be drawn into a wire strand can also be woven into a plain weave mesh form. Plain weave mesh consists of wires crossing alternately over and then under one another as well as having adjacent wires 180° out of phase. The mesh is typically specified by the number of strands per inch in the x and y directions (e.g., 100 x 100 mesh) which is exactly 1 higher than the number of apertures per inch. If the mesh is woven in a square format the number of strands per inch is commonly only stated only once (e.g., 100 mesh). Custom weaves are available in non-square/rectangular formats (i.e., different number of wires per inch in the x direction than the y direction – e.g., 80 x 60 mesh).

The minimum wire diameter and the number of strands per inch will vary with the physical properties of the base metal. Dontech standard mesh counts range from 22 to 255 strands per inch with wire diameters ranging from 0.001 to 0.0044 inches. It is common to interchange opening per inch (OPI) with mesh but the OPI for woven mesh is technically 1 lower than the mesh count (e.g., 100 mesh = 99 OPI).

The proper combination of wire diameter, material type, and mesh count allows for a stable, high wire-to-wire pressure. Dontech has also redesigned and retooled looms to further enhance the uniformity of the weave, allowing for the highest quality meshes.

Standard Dontech wire materials include copper and stainless steels (type 316 and 304). Dontech also utilizes custom materials for wire, such as nickel, phosphor bronze, and metalized polyester. The large variety of wire meshes, both industry standard and unique, gives Dontech unparalleled ability to match wire meshes to the full spectrum of optical and shielding requirements.

Standard Dontech wire materials include copper and stainless steels (type 316 and 304). Dontech also utilizes custom materials for wire, such as nickel, phosphor bronze, and metalized polyester. The large variety of wire meshes, both industry standard and unique, gives Dontech unparalleled ability to match wire meshes to the full spectrum of optical and shielding requirements.

Wire meshes (especially stainless steel meshes) are conductively plated, to increase the level of shielding and ensure shielding uniformity. Dontech’s standard plating consists of a multilayer plating for stainless steel meshes. The mesh is commonly plated with silver per Federal Specification QQ-S-365, type 1, grade B, with a thickness of 0.0001″ (2.54 µm) to 0.0002″ (5.08 µm) following preparation of the base material. This silver layer fuses the wire crossover points and sheaths the wire with a layer of silver. The silver plating physically fuses or welds the wires in place, resulting in better optics for the higher open area meshes. The net result is a significant improvement in the material’s shielding effectiveness and shielding uniformity.

A multilayer plating that encapsulates the mesh in a conductive flexible seal is added for stability and aesthetics. This process prevents silver migration, allows for the desired level of corrosion resistance, and produces the dark outer surface color. The outer layer is a proprietary alloy that blackens the mesh and lowers the gloss. This outer layer improves the aesthetics of a panel using wire mesh laminated under a clear substrate when exposed to high ambient light source (i.e., potential source of reflection).

Dontech can adjust plating processes to meet customer requirements, for example, it is common for the thickness of the silver to be halved or doubled for lower or higher shielding requirements, respectively. Dontech also offers a high transmittance plating that can improve the transmittance of a wire mesh by more than 10% and a low diffuse process for reducing photopic reflections off the mesh.

Conductive Platings

- Improve Mesh EMI/RFI Shielding

- Improve Galvanic Compatibility

- Improve Optical Properties

- Standard Sheet Size of 24” x 24”

Integrations

and is available laminated in optical substrates including

glass, polycarbonate, acrylic, and polyester films.

Dontech’s OFW and MEM meshes can be custom oriented and plated to produce the best optical and shielding results and integrated into optical substrates such as glass, acrylic, polycarbonate, and flexible polymer films.

Mesh can be applied to frames and bezels with perimeter attachment, as well as to the rear surfaces of resistive or PCAP touchscreens with full optical bonds. Further enhancements include conductive gaskets, tapes, and busbars applied to meshes for optical EMI/RFI shielding of electronic displays, touchscreens, instrumentation, enclosures, and optics.

DONTECH & Optical Mesh & Plated Mesh Sheets

Dontech has extensive engineering and technical support resources that can assist you with your OFW mesh design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery. We will integrate our optical filters and other enhancing components into touchscreens, displays and systems to the level that is needed by our customers.