Home / Industries /

Precision Optics

Precision Optics

Dontech designs and manufactures precision optics for applications including targeting, imaging, and sensing optical assemblies for ground, sea, and air-based military craft, heads-up display optics, laser optics, and structural optics for military vehicles with specialized properties including EMI/RFI shielding and other survivability measures. We also produce custom precision optics for applications including medical imaging, analytical and test instruments, and heavy industrial equipment (e.g., commercial aircraft de-icing systems). Common enhancements: Precision polished glass and crystalline substrates, high performance thin film coatings, optical EMI/RFI shielding (i.e., conductive optical grids and transparent conductive coatings), transparent heating, and precision laminations.

Solutions

Optical EMI/RFI Shielding

Transparent Heating

Specialty Substrates, Coatings and Laminations

Optical EMI/RFI Shielding

Transparent Heating

Specialty Substrates, Coatings and Laminations

Key Elements

- Glass with Precision Polishing, Finishes, Coatings, Treatments, and Laminations

- Crystalline Materials with Precision Polishing, Finishes, and Coatings

- Specialty Polymers with Precision Finishes, Coatings, and Laminations

- High Performance Polarizers

- Antireflective – For UV, Visible, NIR, MIR & FIR spectrums

- Transparent Conductive – For visible and part of the NIR spectrums (out to 1600nm, dependent on substrate and coating conductivity) and etched to extend out to 25 microns.

- Dichroic

- Narrow Band Pass

- Short Wave Pass

- Long Pass

- Band Rejection/Laser Blocking

- Mirrors

- Beamsplitters

- Metallic

- Mirrors

- Conductive Buses

- EZKlean™ Brand Hydrophobic and Oleophobic Coatings

- Custom

-

High Performance Transparent Conductive Coatings – Visible, and part of the NIR spectrum (out to 1600nm, dependent on substrate and coating conductivity)

-

Conductive Optical Grids – UV through FIR

-

Etched and Patterned Grids of Thin Film Deposited Coating

-

Plated Woven Meshes

-

Low Temperature Compensation

-

Transparent Conductive Coating Heaters – visible and part of the NIR spectrum (out to 1600nm, dependent on substrate and coating conductivity)

-

Conductive Optical Patterns – UV through FIR

-

Etched and Patterned Grids of Thin Film Deposited Coatings

-

-

Precision Machining of Mounting Frames

-

Metals

-

Polymers

-

-

Precision Bonding into Mechanical Mounting Frames

Ruggedization and Other Environmental Compliance

- Salt Fog

- Temperature and Humidity

- Shock and Vibration

- Altitude

- Thermal Shock

- Other MIL-STD-810 Durability Requirements

How We Address Your Needs

Dontech filters and precision optics assemblies can address the functional requirements of these applications including impact resistance/ruggedization, reflection control, EMI/RFI shielding, low and high temperature mitigation, and other demanding environmental needs.

Dontech utilizes various substrate materials to meet the specific optical performance requirement of an application. Substrate choice is customized based on the application’s needs. Options include crystalline substrates such as sapphire and zinc sulfide, glass such as borosilicate, chemically strengthened soda lime, and safety-laminated, and polymers such as acrylics and polycarbonates.

High-performance thin film coatings and specialty laminations can be tuned to the application’s transmitting or reflecting wavelength requirements. Dontech optics are often tuned for the UV to far IR spectrum requirements. Dontech addresses visible and NIR needs with a family of precision optical lamination technologies and capabilities. These allow us to create multilayer, specialty laminations of similar and dissimilar materials. For all spectrum optics, Dontech has several potting processes for the precise alignment and low stress mounting of the optics support structure or frames for easy and accurate attachment to the next higher-level assembly. Our processes have been refined to help address precise optical wedging requirements and structural needs, as the end usage requires.

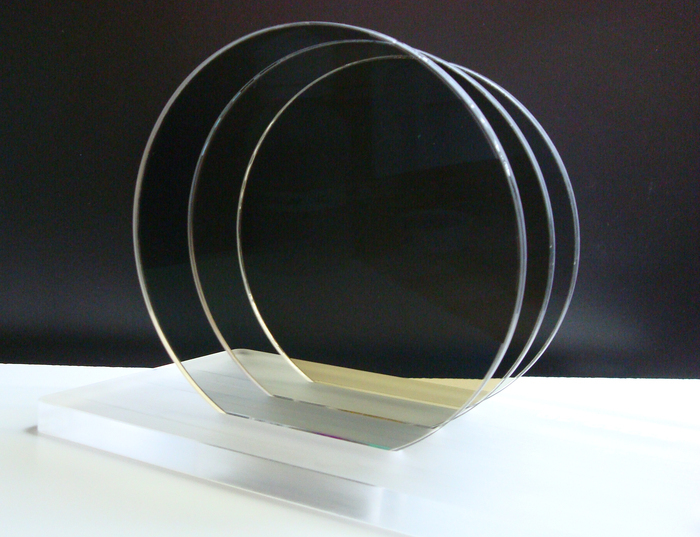

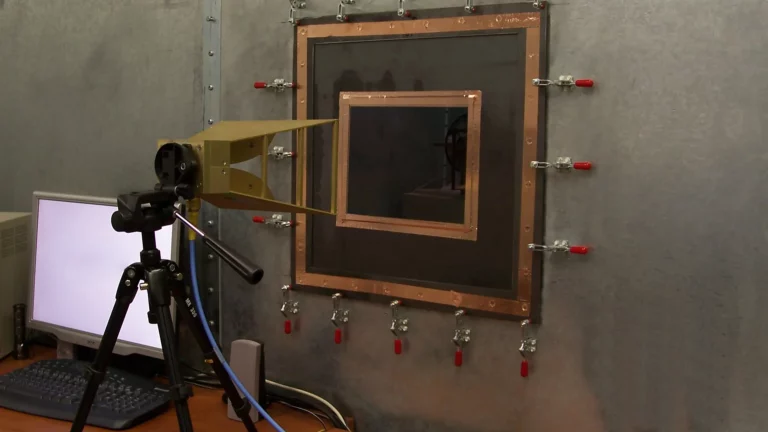

The EMI/RFI shielding technologies commonly incorporated into Dontech precision optical filters provide countermeasures to both susceptibility and emissions requirements. For very high-level shielding over all wavelengths and as the only solution for longer wavelength IR applications, Dontech manufactures optical shielding solutions with fine conductive grids which include both patterned (e.g., etched) thin film deposited metal films and conductively electroplated optical fine wire (OFW) woven meshes. Dontech’s standard OFW mesh is available from 50 through 255 openings per inch and patterned/etched mesh is available from 10 through 160 openings per inch. For lower shielding requirements that are also within the visible and NIR spectrums, Dontech produces products with transparent conductive (e.g., ITO) coatings, offering resistances as low as <1 ohm/square.

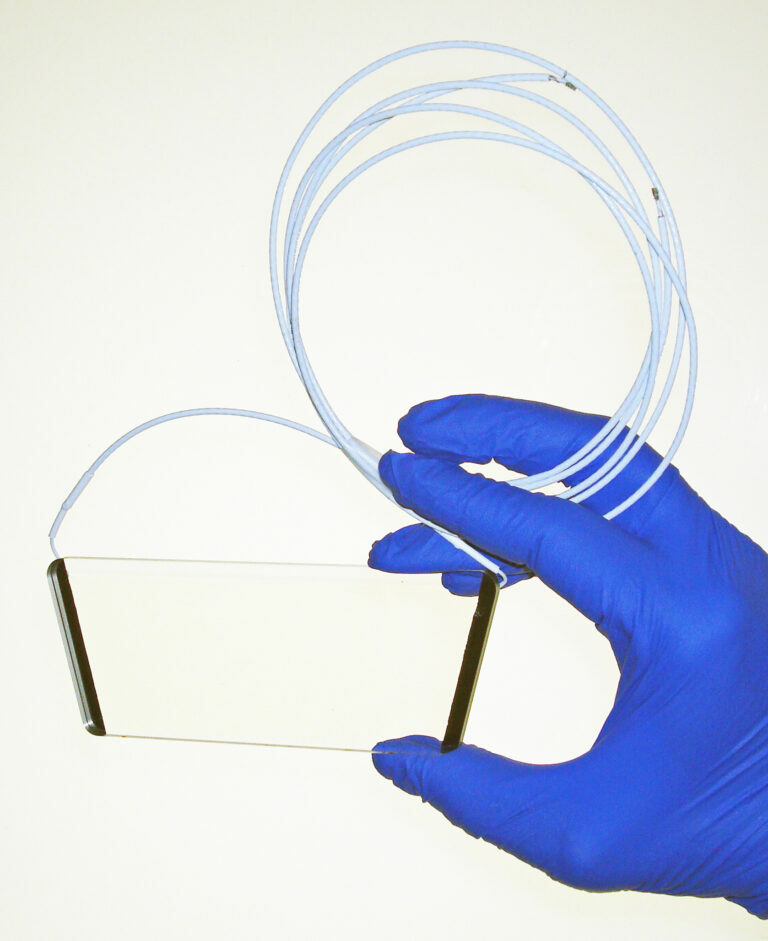

Dontech transparent heaters used in precision optics applications such as laser, sensor, and camera windows incorporate exceptionally uniform conductive coatings, proprietary bus design, and wire attachments to maintain the integrity of the optics under demanding operating conditions. Heaters are fabricated from polished substrates such as zinc sulfide, sapphire, or borosilicate glass and are equipped with thermal sensors to maintain a controlled and consistent performance. Typically, Dontech recommends a continuous conductive coating for visible and NIR applications. For transmitting applications in the mid-IR and far-IR conductive coatings must be patterned.

We have extensive in-house manufacturing and metrology/testing capabilities to ensure the accurate control of coating, optical, flatness, thermal, and mechanical parameters in our products. High reliability systems for precision optics applications have very expensive qualification and requalification protocols. Dontech’s control of its performance enhancing processes in-house allows us to support most no-change products for well over 20 years. This also gives us the unique ability to support many legacy products for the program’s or product’s useful lifetime.

Dontech transparent heaters used in precision optics applications such as laser, sensor, and camera windows incorporate exceptionally uniform conductive coatings, proprietary bus design, and wire attachments to maintain the integrity of the optics under demanding operating conditions. Heaters are fabricated from polished substrates such as zinc sulfide, sapphire, or borosilicate glass and are equipped with thermal sensors to maintain a controlled and consistent performance. Typically, Dontech recommends a continuous conductive coating for visible and NIR applications. For transmitting applications in the mid-IR and far-IR conductive coatings must be patterned.

Case Studies

External Optical Filter Defogging and Deicing Solution

DONTECH & Precision Optics

Dontech has extensive engineering and technical support resources that can assist you with your military, medical or industrial optical system enhancement design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery. We will integrate our optical filters and other enhancing components into touchscreens, displays and systems to the level that is needed by our customers.