Home / Industries /

Military

Military

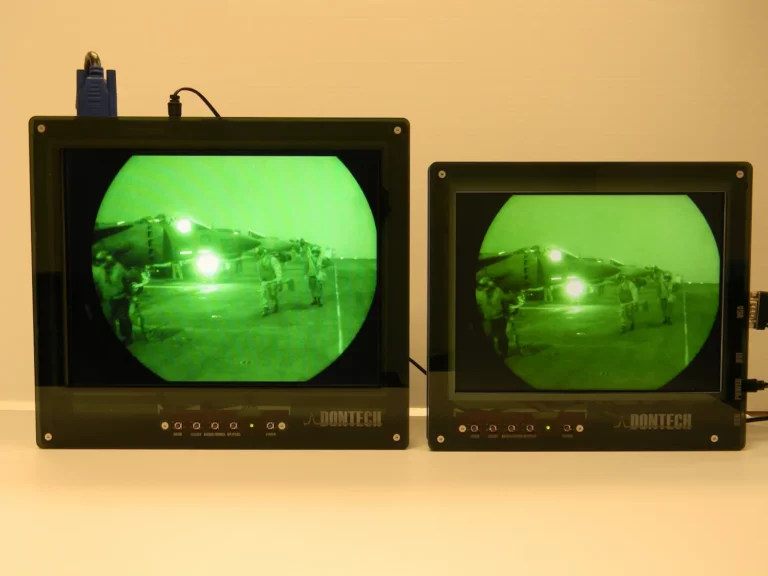

Dontech designs and builds optical filters and enhanced touchscreens and display assemblies to meet demanding military applications worldwide. Military optical components and optical assemblies are key Dontech markets. Current military applications include ruggedized display assemblies for ground, sea, and air-based military, ruggedized laptop displays, mobile communication and GPS devices, hand-held electronics such as radios and tablets, avionic displays, and targeting and sensor systems. Common enhancements include EMI/RFI shielding, shock and vibration ruggedization, night vision imaging system (NVIS) compatibility, and transparent heating solutions.

Solutions

Optical Filters

Enhanced Touchscreens

Display Solutions

Optical Filters

Enhanced Touchscreens

Display Solutions

Key Elements

As an AS9100D and ISO-9001:2015 designer and manufacturer of optical filters and thin film coatings for demanding applications, Dontech builds a variety of optical products with the following performance enhancing elements:

-

High Performance Transparent Conductive Coatings

-

Conductive Optical Grids

-

Etched and Patterned Conductive Optical Grids

-

Plated Woven Meshes

-

- High Performance Conductive Buses

-

EMI/RFI Shielding and Environmental Gaskets

Low and High Temperature Compensation

-

Reflective Hot Mirrors

-

Absorptive Filters – Front surface and backlighting enhancements

- Impact Resistance (e.g., boot kick compliance)

- Shock and Vibration Improvement

- Sand and Dust Protection

- Other MIL-STD tests

How We Address Your Needs

Demanding military environments require high-level and mission-critical performance from tactical vision systems, vehicle maintenance, and other support devices. Dontech’s filters and display assemblies can address the functional requirements of the application including impact resistance, sunlight readability/contrast enhancement, EMI/RFI shielding, low and high temperature mitigation, night vision imaging system (NVIS) compatibility, and environmental and mechanical ruggedization. Dontech utilizes various substrate materials to meet the performance, weight, and cost requirements of an application.

Whether constructed from a chemically strengthened glass or plastic material (e.g., PMMA, polycarbonate), Dontech’s products are designed to exceed impact requirements including boot, wrench, and ball-drop tests. Sunlight readability and contrast enhancements are achieved through active and passive enhancement of the backlighting and film layers of LCDs, antireflective and antiglare surface coatings, optical bonding technologies, and polarization optimization to conserve power consumption and reduce internal reflections typically resulting from the touchscreen and LCD film interfaces.

EMI/RFI Shielding

Electronic communications produce radio frequency emissions that can disclose sensitive information and intelligence if intercepted. The EMI/RFI shielding technologies incorporated into Dontech filters provide countermeasures to ensure information security. Our optics shield for both radiated susceptibility and radiated emission compliance. Dontech manufactures optical shielding solutions with fine conductive optical grids, which includes both patterned (e.g., etched) metal films and conductively electroplated woven fine wire meshes. Standard Dontech woven mesh is available from 50 through 255 openings per inch (OPI) and from 80 to 160 OPI for patterned/etched mesh. For improved optical performance and lower shielding requirements, transparent conductive (e.g., ITO) coatings with resistances as low as <1 ohm/square are available.

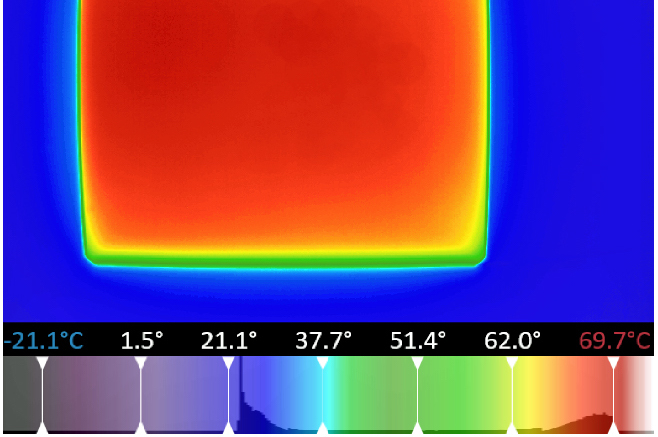

Thermal Management, NIR Control, and Ruggedization

Transparent heaters and solar reflecting components can extend the operational temperature range of display assemblies and sensing optics. Dontech produces NVIS filtering technology that is integrated into the display assembly and tailored to the application needs (i.e., NVIS friendly to fully compliant to MIL-STD-3009). Additionally, Dontech can incorporate features such as mounting frames, bezels, and gaskets for environmental, water immersion, and shock and vibration ruggedization. Dontech’s optics integration solutions are highly customizable, providing the broadest range of highly customizable optical and shielding solutions available.

Display and Touchscreen Solutions

Military Precision Optics Solutions

Precision optics and assembly applications are a key Dontech military market. Dontech designs and manufactures precision optics for applications including targeting, imaging, and sensing optical assemblies for ground and sea-based military craft. We also manufacture a broad range of large optics with more structural properties for military vehicles for land, sea, and air platforms. See precision optics product page for more details.

Military Avionic Display Solutions

Dontech designs and manufactures performance enhancing optics for military cockpit heads up and head down displays for both fixed and rotary wing applications. See avionic industry page for more details on this product family.

Case Studies

Military Display for a Mission Command Network

DONTECH & Military

Dontech has extensive engineering and technical support resources that can assist you with your military display and optical system enhancement design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery. We will integrate our optical filters and other enhancing components into touchscreens, displays, and systems to the level that is needed by our customers.