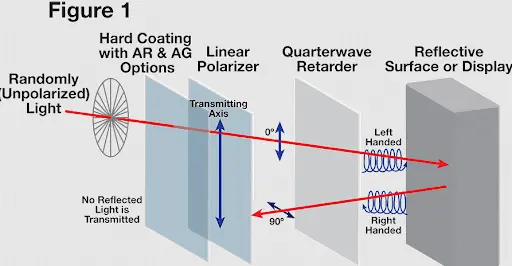

Circular polarizers (CPs) are used to enhance the readability of emissive displays by suppressing single mirror internal reflections (by up to 99%) and improving the display’s contrast.

Circular polarizers are typically produced by the lamination of several different materials including a linear polarizer (LP), a 1/4 wave (QW) retarder, and often a front surface hard coating (see Fig. 1). Because LCD polarizer films are thin (0.5 mm) and sensitive to moisture, circular polarizers are often combined with rigid, non-birefringent optical substrates (e.g., acrylic, glass, triacetate) to improve their physical properties. When properly designed, circular polarization provides a very effective internal reflection reduction (e.g., glare) for optical systems including displays, touchscreens, cameras, and sensors. Particularly in high ambient light environments, circular polarizers benefit electronic displays such as:

*Circular polarizers are typically used on resistive touchscreen with LCDs. They must be properly oriented as the display’s output is linearly polarized. A properly oriented linear polarizer (LP) in an LCD application is a more effective means of improving contrast when a touchscreen is not employed. For lower cost LCDs the LPs on the LCD can be removed and replaced with higher polarizing efficiency LPs to improve the displays contrast.

AR Coating & Anti-Glare (AG) Hard Coatings Can Be Your Top Layer

Anti-reflective (AR) and Anti-Glare (AG) hard coatings are commonly used to improve LCD display image quality and sunlight readability through reduced front surface reflections and contrast enhancement.

How a Circular Polarizer Functions

Dontech’s standard CP is a 44% neutral density gray (i.e., total luminous transmittance of 44% over the visible spectrum). These can be embedded in rigid substrates, including acrylic and glass. The LP component is iodine doped polyvinyl alcohol (PVA) type. Dontech also offers a non-PVA circular polarizer (i.e., dyed LP), which improves the environmental performance but decreases the polarizing efficiency.

Dontech’s CPs are further enhanced by laminating the neutral density gray polarizer to an optically matched color selective filter appropriate for the application requirements (e.g., display output). For instance, with an electroluminescent display, the circular polarizer may be combined with an amber long pass filter. To assure maximum performance, the linear polarizer within the circular polarized material must be properly aligned to the display and for the intended viewing angle of the display.

Dontech’s standard circular polarizers are left-handed, however each handedness is available. The handedness of a circular polarizer is referred to as the “sense” of the CP. The circular polarizer may be described as left- or right-handed. CPs are always expressed as having handedness or helicity, which is determined by the position of the slow axis of the retarder being to the right or left of the linear polarizer as viewed from the retarder side of the filter.

Dontech has extensive engineering and technical support resources that can assist you with your polarizer design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery We will integrate our optical filters (OFED) and other enhancing components into touchscreens (DTS), displays (DES) and systems to the level that is needed by our customers.

Dontech is an AS9100D and ISO-9001:2015 certified designer and manufacturer of optical filters, laminations, and thin film coatings for the precision optics, display, and touchscreen markets.

Since 1971, we have designed and manufactured custom components that enhance the performance of optical systems from concept to final system delivery.