Home / Products /

Batch Toll Coating Thin Film Services

Batch Toll Coating Thin Film Services

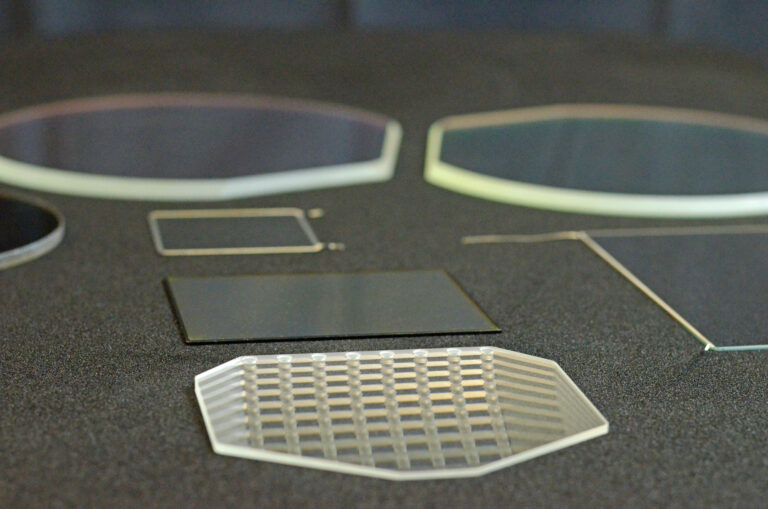

Dontech’s in-house physical vapor deposition (PVD) coating services include DC and AC magnetron sputtering, ion-enhanced E-beam evaporation, and chemical vapor deposition (CVD). The thin film coatings can be applied to a variety of rigid and flexible substrates including glass, crystalline and plastic substrates.

Performance-enhancing thin film coatings are applied to substrates to improve the optical, electrical, and environmental properties of the base materials. Common coatings applied to the surfaces of the substrates include antireflective coatings, nonconductive oxides, conductive metallic coatings, mirrors, transparent conductive coatings (e.g., EMI/RFI shielding, heaters), dichroic filters (e.g., short wave pass, band pass, long pass), heat reflection or thermal management coatings, and electrostatic discharge control.

Performance Enhancing Design Elements

Common Coating Types

1 to 100+ layer coating stacks with individual layer thickness ranging from 100 to 10,000 angstroms can be applied to a broad range of materials.

- Antireflective Coatings – Single layer and multilayer; designed for UV, visible, NIR, MIR, and FIR (out to 25 microns) for substrates with and index from 1.47 to 4.0 and Angle of Incidence (AOI) from 0 to 60 degrees

- Non-Conductive Oxides – (e.g., SiO2, TiO2, AlO2)

- Conductive Metallic Coatings – (e.g., Silver, gold, copper, chromium, nickel, nichrome, stainless steel, palladium, platinum, titanium) which can be patterned (e.g., photoetched, laser ablated)

- Mirrors

- Dielectrically enhanced metallic

- Dichroic

- Transparent Conductive Oxides – (e.g., ITO, AZO)

- < 1 ohm/sq to >100 ohms/sq

- Dielectrically enhanced

- Dichroic Filters

- Narrow Band Pass

- Short Wave Pass

- Long Pass

- Band Rejection

- Beamsplitters

- Other – Developmental

Common Substrates

Crystalline Substrates

- Fused Quartz

- Sapphire

- Silicon (Si)

- Zinc Sulfide (ZnS)

- Zinc Selenide (ZnSe)

- Other

Glass Substrates – Options include annealed, tempered, and chemically strengthened

- Aluminosilicate

- Borosilicate

- Boro-aluminosilicate

- Borosilicate-crown (N-BK7)

- Fused Silica

- Soda Lime

- Other

Plastic Substrates

- Acrylics (PMMA)

- Allyl Diglycol Carbonate (ADC)

- Cyclo Olefin Polymers (COP)

- Foils

- Fluoropolymers

- Glass

- Membrane Materials

- Nylons

- Polarizers (linear & circular)

- Polycarbonates (PC)

- Polyethylenes (PE)

- Polyethylene Terephthalates (PET)

- Polyethylene Naphthalates (PEN)

- Polyimides (PI)

- Polypropylenes

- Triacetate (TAC) or Cellulose Triacetate

- Vinyls

- Woven and Non-Woven Fabrics

- Other

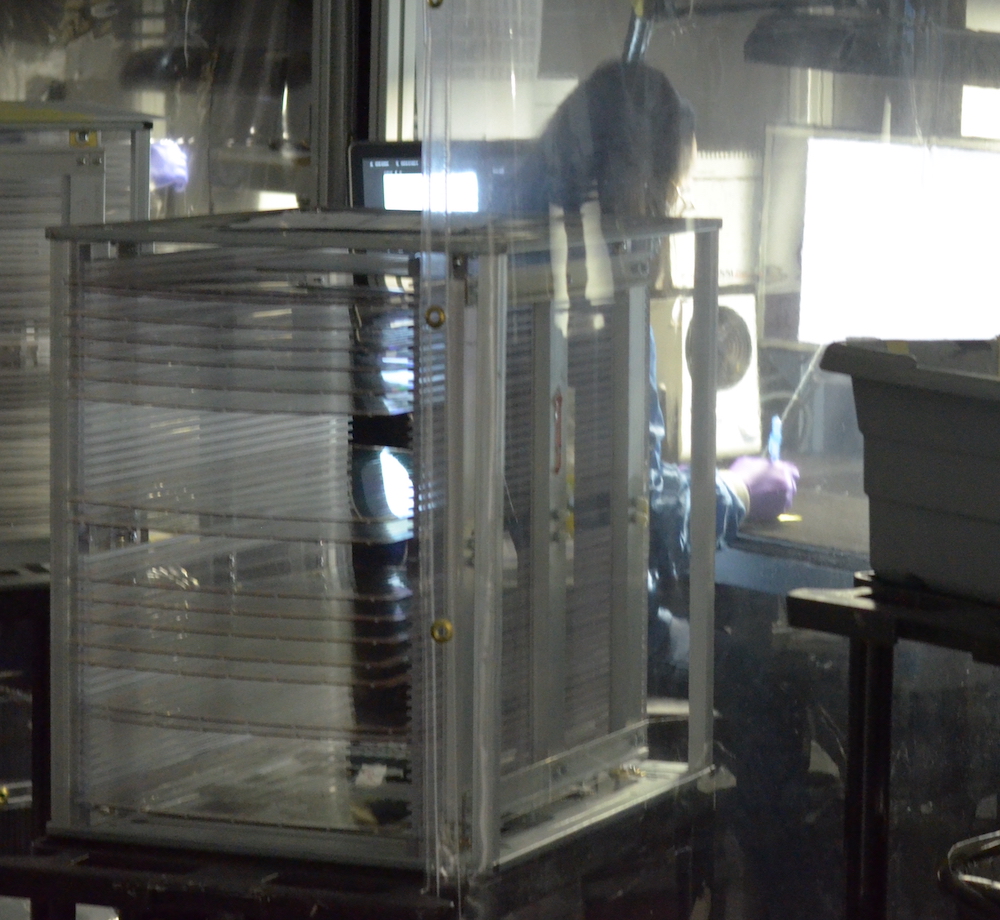

Toll Coating Services

In addition to leveraging our extensive supplier network to source all raw materials and provide a complete thin film coated product solution, Dontech also offers toll coating services. We will gladly coat customer-supplied rigid or flexible substrates in batch or roll-to-roll processes to the extent of the capabilities listed above.

Integrations

Dontech can provide integration services to incorporate the coated element or optic into the next higher-level assembly, including mounting frames and enclosures ranging in size from small to large format structural applications. As needed, these operations can be performed in cleanrooms ranging from ISO 5 [Class 1,000] through ISO 8 [Class 100,000] with ISO 5 [Class 100] through ISO 6 [Class 1,000] work centers. These spaces are environmentally controlled (i.e., humidity, temperature, ionized HEPA filtered air, and ESD controlled environments).

Metrology

Dontech has extensive optical, physical, and general product testing capabilities. Common tests include reflection and transmission (190nm through 25 microns), wedging, wavefront distortion, conductivity (non-contact and 4-point probe), temperature and humidity, salt fog, salt solubility, adhesion, and abrasion. Additionally, we can run destructive and non-destructive testing to characterize the performance of our thin film coatings.

We offer full traceability down to the part level and can provide necessary support reports for customers qualifying builds or investigating changes. Our broad metrology abilities also allow us to reverse engineer a product when required to help create a direct equivalent to an existing product. Everything that we produce is custom. Subject to minimum run charges, we will run from 1 of a custom item to 100K+.

In addition to metrology to characterize the performance of our coatings, we will inspect incoming and outgoing materials for compliance with the agreed upon blemish specifications. We work to a broad range of industry specifications (e.g., MIL-PRF-13830 – scratch and dig standard) and to custom specifications as well. We will cleanroom package as required.

DONTECH & Batch Toll Coating Thin Film Services

Dontech has extensive engineering and technical support resources that can assist you with your custom thin film coatings design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery.