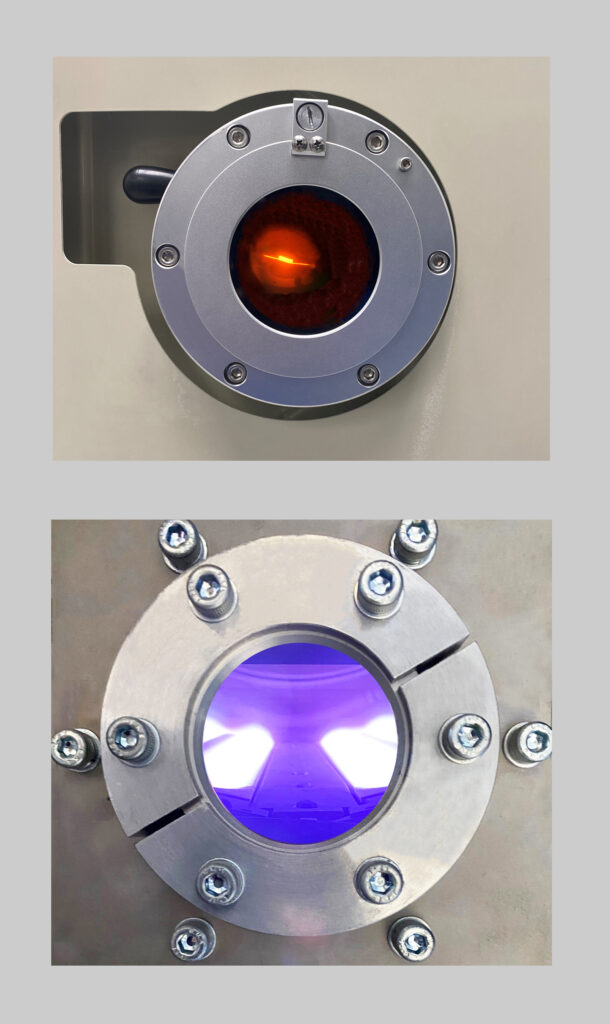

Dontech has an extensive array of high energy, thin film vacuum deposition systems for applying optical coatings to different types of substrates. Processes include DC and AC magnetron sputtering, ion-enhanced (IAD) e-beam evaporation and chemical vapor deposition (CVD). Our coating abilities range from a simple single-layer quarter wave optical layer applied to an optical substrate that reduces specular reflections to a very complex 100-layer dielectric optical stack dichroic filter that tightly controls the reflections and transmissions of light over a broad spectrum.

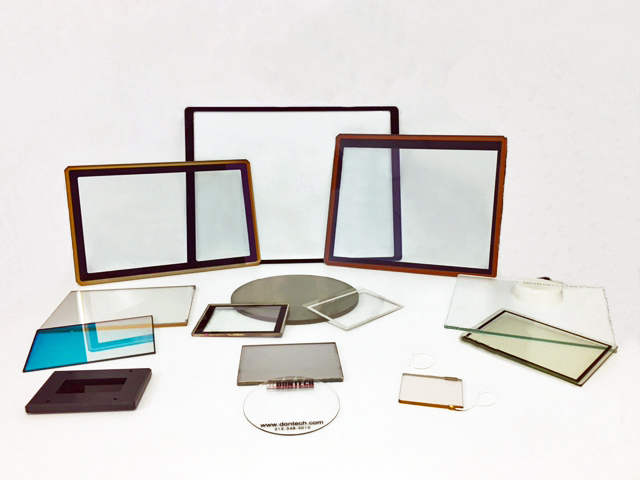

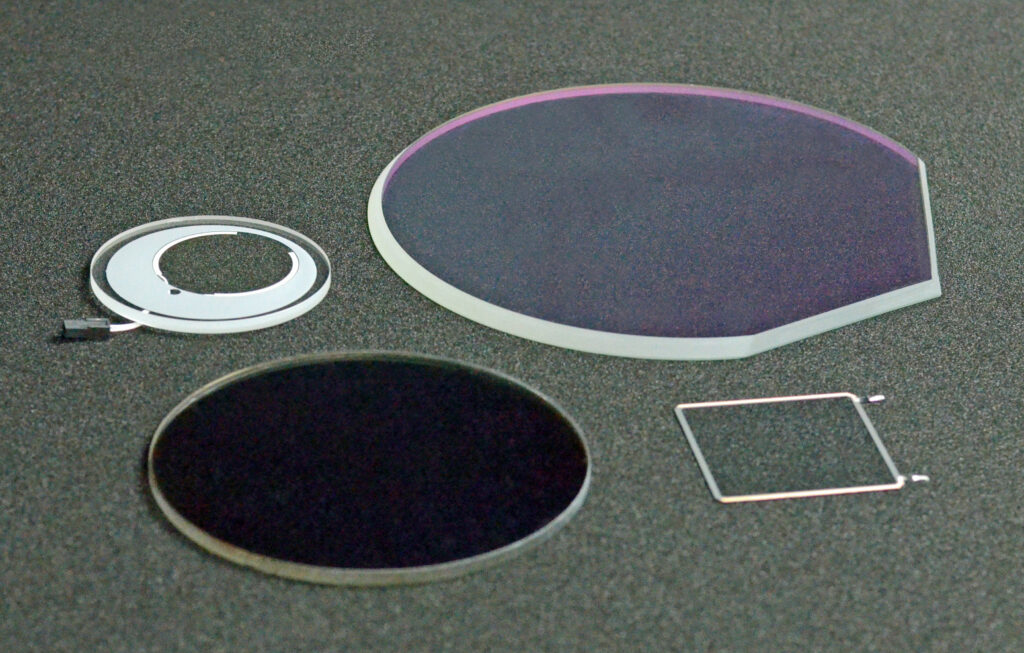

Dontech designs and applies thin film coatings on glass, plastic, and crystalline substrates. We coat rigid and flexible substrates. We customize our coatings for the optical spectrum from UV, Visible, Near IR and, through part of the Mid IR (out to 25 microns). Dontech’s optical coatings instill optics-enhancing features while also meeting a broad range of military, medical, and other industry durability requirements (e.g., high laser damage threshold).

1 to 100+ layers coating stacks with individual layer thickness ranging from 100 to 4,000 angstroms can be applied to a broad range of materials.

1 to 100+ layers coating stacks with individual layer thickness ranging from 100 to 4,000 angstroms can be applied to a broad range of materials.

Common Substrates

Crystalline Substrates

Glass Substrates – Options include annealed, tempered, and chemically strengthened.

Plastic Substrates

Dontech has extensive engineering and technical support resources that can assist with your thin film coating selection and design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery. We will integrate our optical filters and other enhancing components into touchscreens, displays, and systems to the level that is needed by our customers.

Since 1971, we have been creating components to improve the performance of optical systems, supporting our customers from concept to final system delivery. Dontech engineers, manufactures and integrates custom parts for optical, electronic display, touchscreen, and optical and electronic assembly markets. We also produce functional coatings for components used on satellites and interplanetary spacecraft. We manufacture optical filters, laminations, thin and thick film coatings, precision conductive optical grids, electronic traces, and other enhancements to service the military, avionics, aerospace, medical, industrial and government markets.

We are proud of the partnerships we build with our customers, and we are ready to use our expertise to support your program. Dontech’s Quality Management System is AS9100D and ISO-9001:2015 certified with TUV Rheinland of North America.