Optical bonding improves sunlight readability and enhances mechanical and thermal performance of electronic displays and touchscreens. Dontech is a leading designer and vertically integrated manufacturer of optical filters and touchscreen enhancements. We bond and integrate these enhancing components to displays and touchscreens as a service to our customers.

Optical bonding is the process of adhering two or more substrates, typically using clear liquid or gel adhesives. These adhesives may include silicones, epoxies, acrylics, and acrylated urethanes, with a refractive index properly selected to minimize the reflection losses between the two media. See bonding materials for more information on IMO-bond systems and mechanical configurations for bonding locations and formats.

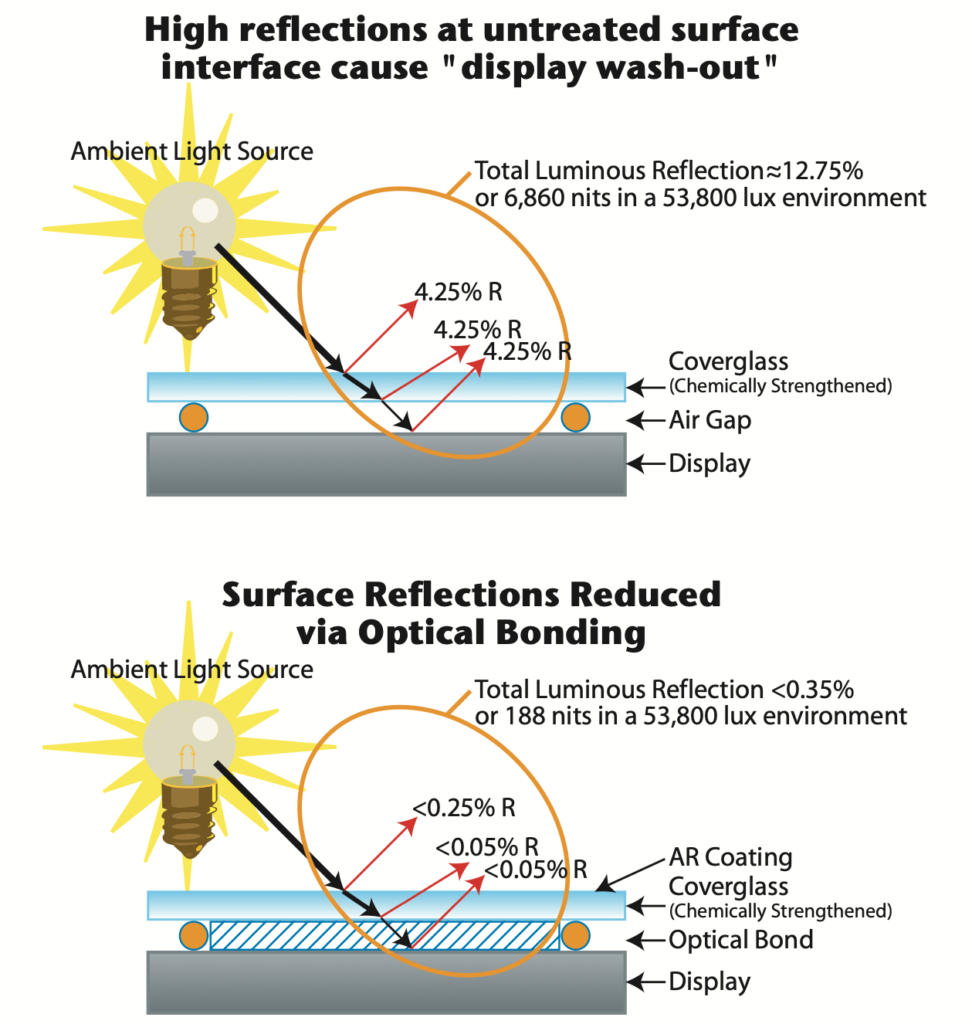

Relative to electronic display applications, optical bonding is the process of affixing an optical filter (typically a glass or plastic substrate) to the surface of the display or touchscreen. As shown in the first figure below, every untreated surface in the optical path of a display system has a reflection loss of about 4.25% (index-dependent) per surface when it transitions from an optical substrate to air or from air to an optical substrate. This equates to a transmission loss for the displayed information, and under high ambient light conditions, it also creates a significant reflection issue. In a high ambient light environment (> 30,000 nits), a 4.25% reflection often exceeds the display’s luminance. The net effect is detrimental to display viewing under high ambient light conditions.

Most commercial off-the-shelf (COTS) displays are not designed for direct viewing in bright, outdoor conditions. Optically coupling a cover glass to the front polarizer of the display virtually eliminates reflections from the rear surface of the optical filter and the front surface of the display system. Front surface reflection can be further reduced with the application of a thin film dielectric layer such as Dontech VAR™ brand broadband antireflective (AR) coating. Dontech VAR™ coatings can have average photopic reflection of less than 0.25% (VAR™-0.25). The second figure below demonstrates the significant performance improvement possible from utilizing Dontech’s IMO-bond™ process combined with our VAR™ coatings at multiple interfaces.

Dontech’s IMO-bond™ process has evolved over 50 years of optical filter and optical coating and lamination design and chemical formulation experience to include many options including custom formulations of optical adhesives. Benefits of the IMO-bond process include:

Dontech has extensive engineering and technical support resources that can assist you with your optical bonding design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery. We will integrate our optical filters and other enhancing components into touchscreens, displays, and systems to the level that is needed by our customers.

Since 1971, we have been creating components to improve the performance of optical systems, supporting our customers from concept to final system delivery. Dontech engineers, manufactures and integrates custom parts for optical, electronic display, touchscreen, and optical and electronic assembly markets. We also produce functional coatings for components used on satellites and interplanetary spacecraft. We manufacture optical filters, laminations, thin and thick film coatings, precision conductive optical grids, electronic traces, and other enhancements to service the military, avionics, aerospace, medical, industrial and government markets.

We are proud of the partnerships we build with our customers, and we are ready to use our expertise to support your program. Dontech’s Quality Management System is AS9100D and ISO-9001:2015 certified with TUV Rheinland of North America.