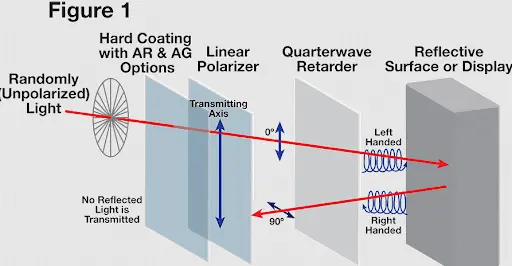

Unpolarized light (e.g., sunlight) consists of wave forms vibrating in all directions. Circular polarizers restrict or control the directions in which polarized or unpolarized signals are allowed to oscillate or vibrate. In display applications, circular polarizers are used to separate the light emitted by the display from unwanted light originating from other internally reflecting sources. They restrict or control the directions that the polarized or unpolarized signals are allowed to oscillate or vibrate. As shown in Fig. 1, a circular polarizer consists of a linear polarizer (LP) and a ¼ wave retarder. The Dontech standard ¼ wave retarders are optimized around the peak visible wavelength (i.e., 550nm). The retardance value is approximately 140 nm.

Unpolarized ambient light entering the display from the outside first passes through a linear polarizer (the first layer of the circular polarizer). When the light ray, now linearly polarized, passes through the ¼ wave retarder, it is separated into two equal component light rays that are ¼ wavelength out of phase with one another (i.e., the phase relationship such that the leading ray is ¼ wavelength ahead of the lagging ray). When these light rays strike a specularly reflecting surface (e.g., the front of a display or internal layer of a resistive touch panel) and are reflected, the phase relationships between the two rays are reversed. Now the previously lagging ray is ¼ wavelength in front. It then re-enters the retarder. The retarder realigns the two rays, and the resultant ray is oriented 90 degrees from the original ray. Thus, by next passing through the linear polarizer again, this ray is blocked. In this way, unwanted reflected ambient light originating outside the display is separated from the desired light emitted by the display, thereby reducing glare and internal reflections, and increasing contrast. The level of blocking is characterized by the polarizer efficiency of the linear polarizer or the extinction coefficient of the circular polarizer.

A “perfect” linear polarizer would transmit 50% of an unpolarized input beam. Two perfect polarizers with their transmission axes crossed will totally extinguish an incident beam and have a polarizing efficiency of 100%. Note the vibration direction of a transmitted wave through a LP is always 90 degrees with respect to the LP transmission axis. Dontech standard linear polarizers have a total luminous transmittance between 40 to 46% of unpolarized light.

The retarder has two principal axes, slow and fast, and it resolves a light beam into two polarized components. The beam parallel to the slow axis lags the one parallel to the fast axis. The “retardance” of a material depends on its birefringence. Birefringence is an intensive quantity and is specifically the difference between the two principal refractive indices or the speeds of the propagation of light within the substrate depending on vibration direction. Note: refractive index (n) is the ratio of the speed of light in a vacuum to the normal speed in a medium. The extreme Δn in a material due to the change in vibration direction is the measure of its birefringence. The birefringence of a material remains constant no matter what the size or orientation of the material. Retardance is similar but it is an extensive quantity. For example, if you double a retarder’s thickness the retardance is doubled. Note, a retarder has no effect on an unpolarized beam of light.

Circular polarizers are expressed as having handedness or helicity, which is determined by the position of the slow axis of the retarder being to the right or left of the linear polarizer as viewed from the retarder side of the filter. Dontech standard circular polarizers are left-handed. However, Dontech can configure a CP to either handedness.

Dontech has extensive engineering and technical support resources that can assist you with your polarizer design needs. Our technical staff have diverse backgrounds relevant to high-performance display and precision optics markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery We will integrate our optical filters (OFED) and other enhancing components into touchscreens (DTS), displays (DES) and systems to the level that is needed by our customers.

Since 1971, we have been creating components to improve the performance of optical systems, supporting our customers from concept to final system delivery. Dontech engineers, manufactures and integrates custom parts for optical, electronic display, touchscreen, and optical and electronic assembly markets. We also produce functional coatings for components used on satellites and interplanetary spacecraft. We manufacture optical filters, laminations, thin and thick film coatings, precision conductive optical grids, electronic traces, and other enhancements to service the military, avionics, aerospace, medical, industrial and government markets.

We are proud of the partnerships we build with our customers, and we are ready to use our expertise to support your program. Dontech’s Quality Management System is AS9100D and ISO-9001:2015 certified with TUV Rheinland of North America.