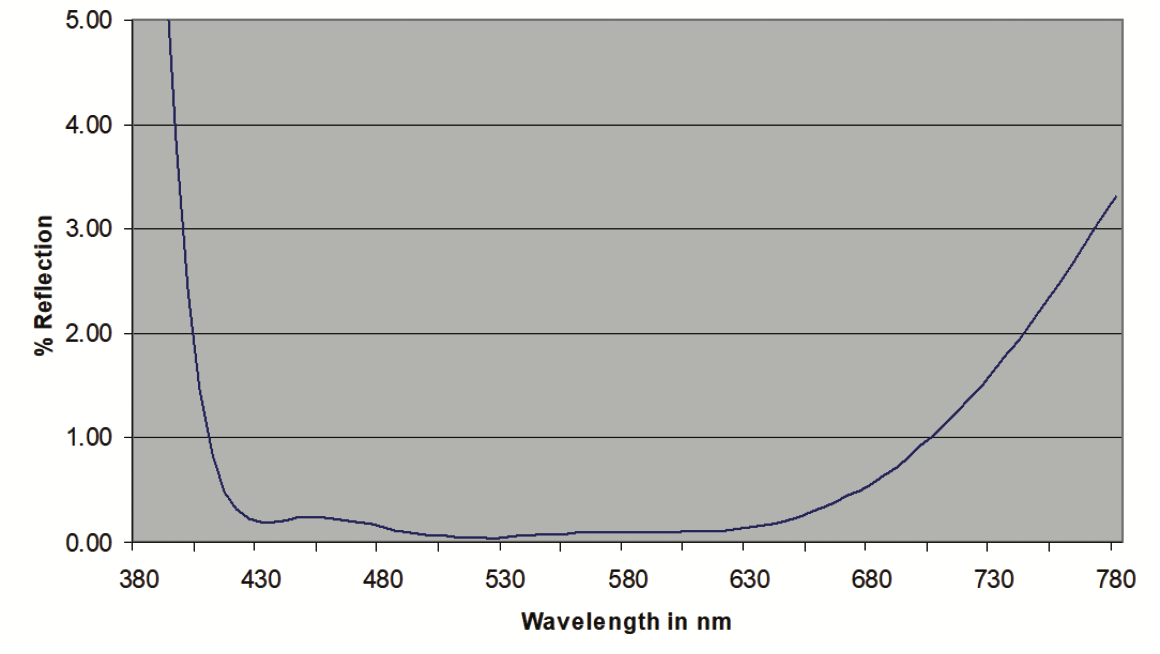

VAR-0.25 is a broad band antireflection coating that is commonly used in demanding sunlight readability applications.

Reflection:

The reflection of the coating shall meet the reflection reducing requirements of MIL-C-14806.

Adhesion:

The coating shall show no evidence of damage when an approved tape is pressed firmly against the coated surface and quickly removed normal from the surface. (Reference MIL-PRF-13830B, Appendix C, para. C.4.5.12)

Abrasion:

The coating shall show no evidence of deterioration after being subjected to a 40-rub eraser test using a rub force of 2-2-1/2 lbs. (Reference MIL-PRF-13830B, Appendix C, para. C.4.5.10)

Humidity:

The coating shall show no evidence of deterioration after being subjected to a continuous exposure of 120°F ± 4°F and 95-100% relative humidity. Following exposure, the coating shall pass the Abrasion (eraser) test with no evidence of deterioration. (Reference MIL-PRF-13830B, Appendix C, para. C.4.5.8)

Salt Solubility:

The coating shall show no evidence of deterioration after being subjected to immersion for a period of 24 hours in a solution of water and 170 grams of salt per 3.8 liters of water. Following exposure, the coating shall pass the Abrasion (eraser) test with no evidence of deterioration. (Reference MIL-PRF-13830B, Appendix C, para. C.4.5.7)

Temperature Shock:

The coating shall show no evidence of deterioration after being exposed to a temperature of 160°F, then -65°F and then 160°F again for 4 hours each. Transfer time between temperatures to be minimal. Following exposure, the coating shall pass the Abrasion (eraser) test with no evidence of deterioration. (Reference MIL-STD-810, Method 503.5, Procedure 1a)

Salt fog:

The coating shall show no evidence of deterioration after exposure to a salt spray fog for a continuous period of 24 hours in accordance with ASTM B117. Following exposure, the coating shall pass the Abrasion (eraser) test with no evidence of deterioration. (Reference MIL-STD-810, Appendix C, para. 4.5.9)

Additional specifications can be integrated into design considerations including fluid exposure to solvents, fuel, cleaning fluids, and other chemicals.

Since 1971, we have been creating components to improve the performance of optical systems, supporting our customers from concept to final system delivery. Dontech engineers, manufactures and integrates custom parts for optical, electronic display, touchscreen, and optical and electronic assembly markets. We also produce functional coatings for components used on satellites and interplanetary spacecraft. We manufacture optical filters, laminations, thin and thick film coatings, precision conductive optical grids, electronic traces, and other enhancements to service the military, avionics, aerospace, medical, industrial and government markets.

We are proud of the partnerships we build with our customers, and we are ready to use our expertise to support your program. Dontech’s Quality Management System is AS9100D and ISO-9001:2015 certified with TUV Rheinland of North America.