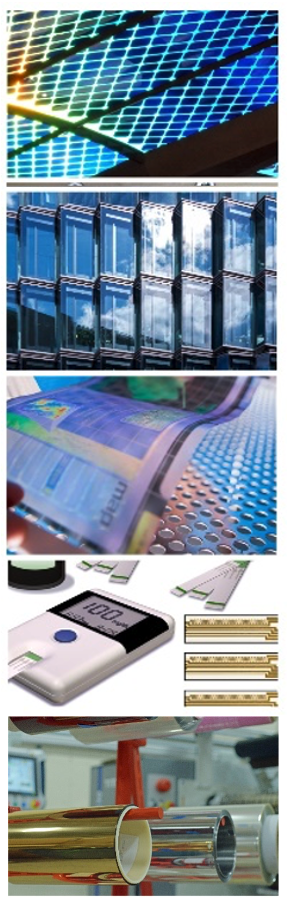

Custom Roll-To-Roll Coatings

Custom thin film coatings include metals, dielectrics, and conductive transparent oxides on flexible substrates.

COATING MATERIALS

CLEANROOM CONVERSION

Engineering Custom And Built-to-Print Products

Dontech designs and applies custom thin film coatings to flexible substrates. Our leading-edge technology translates into enhanced performance for customer assemblies and products. We provide provide high value-added, roll-to-roll (R2R) vacuum deposition services, specializing in the coating and treating of polymeric films and metal foils. All our products are custom or build to print. We support small to Fortune 100 businesses with unique products ranging in quantities from a small pilot roll or hand sheets to over a hundred thousand square meters per order.

Design and Product Manufacturing

Several years ago, Dontech expanded its thin film coating offerings to better serve the high-performance flexible film market. We now offer toll coating services to a broad range of high reliability and performance markets. This initiative was supported by our experienced design and production team, which has been producing optical filters and components which enhance the performance of high-end optical information displays, touch screens and precision optics so they perform as desired in demanding environments for more than 50 years.

We are unique in the industry. Our roll-to-roll thin film coating offerings are supported by our experience with complex, batch, thin film coatings and a broad range of thick film (e.g., hard coatings) gained from servicing high-reliability applications in the military, medical, and avionic markets. When needed, we can rapidly prototype complex designs in batch systems and transfer them successfully to a roll-to-roll process.

Our physical vapor deposition (PVD) process offerings include AC and DC magnetron sputtering, ion-enhanced E-beam evaporation, plasma-enhanced chemical vapor deposition (PECVD), and chemical vapor deposition (CVD). Other vacuum roll-to-roll services include plasma treatments of base substrates for improved adhesion and surface functionalization. Coatings can be applied to one or both surfaces of flexible substrates including a broad family of plastics with and without thick film hard coatings and metal foils. These coatings improve optical, electrical, and environmental substrate properties.

Product Features

CUSTOM COATING TYPES

CUSTOM COATING TYPES

- Antireflective Coatings – single layer & multilayer dielectric stacks

- Dielectrics – non-conductive oxide & nitride coatings

- Electrostatic Discharge Coatings

- Metallic Coatings

- Reflective Coatings – dielectric, metallic, & hybrid

- Substitutional and Interstitial Alloyed Coatings

- Thermal Control/Multilayer Insulation Coatings

- Transparent Conductive Coatings – transparent conductive oxides (TCOs), metallic, alloys and dielectrically enhanced

- Other – Custom & Developmental

COMMON SUBSTRATES

- Acrylics (PMMA)

- Cyclo Olefin Polymers (COP)

- Foils

- Fluoropolymers

- Glass

- Membrane Materials

- Nylons

- Polycarbonates (PC)

- Polyethylenes (PE)

- Polyethylene Terephthalates (PET)

- Polyethylene Naphthalates (PEN)

- Polyimides (PI)

- Polypropylenes

- Triacetate (TAC) or Cellulose Triacetate

- Vinyls

- Woven and Non-Woven Fabrics

- Other

DONTECH THIN FILM COATINGS AND SERVICES

Dontech can build-to-print and apply the coatings per your design. We can toll-coat customer-supplied materials, or we can supply the substrate as part of our services.

We have extensive engineering and technical support resources to assist you with your custom thin film coating design and substrates needs. Our technical staff have diverse backgrounds relevant to high-performance markets. For many of our top customers, we function as an extension of their engineering departments, supporting projects from concept to final system delivery.