Home / Products /

Display & Touchscreen Solutions

Display & Touchscreen Solutions

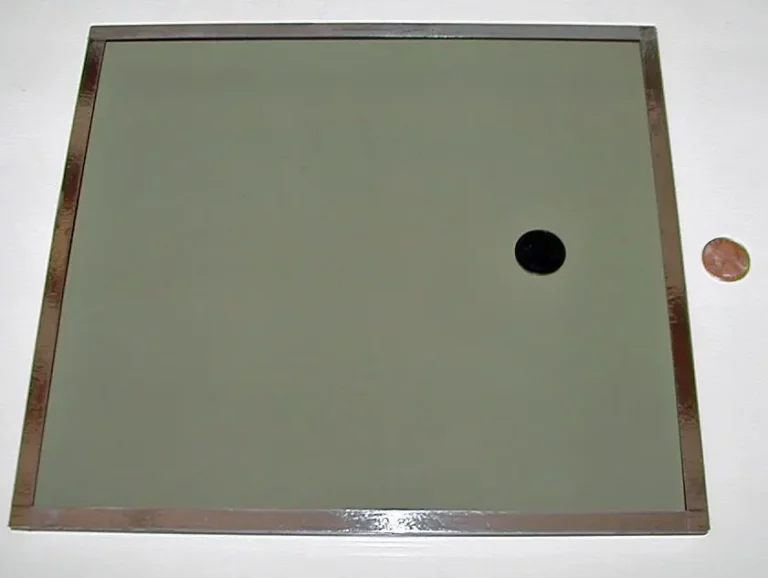

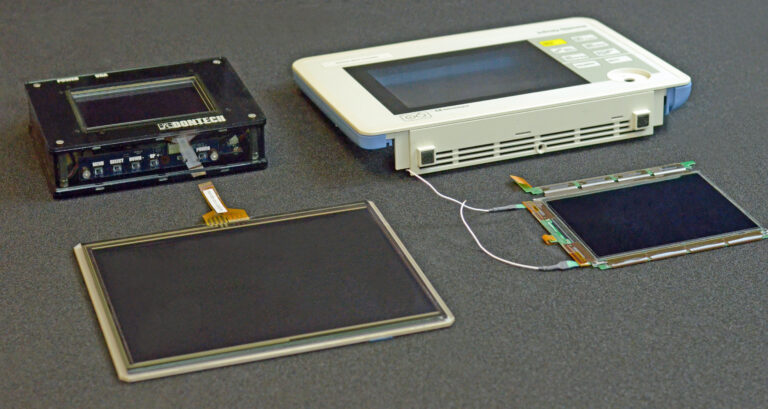

Dontech designs and manufactures custom end-to-end display and touchscreen solutions for demanding avionic (military and commercial), military, medical, government (e.g., homeland security), or industrial applications including rugged, sunlight readable, EMI/RFI shielded display systems. We will fully integrate our optical filters into display and touchscreen assemblies to the level requested by our customers. Dontech can provide custom resistive and projective capacitive (PCAP) touchscreen solutions, and we can perform active and passive backlighting enhancements to LCDs. We can modify customer supplied materials or we can provide everything.

Product Overview

Performance Enhancing Design Elements

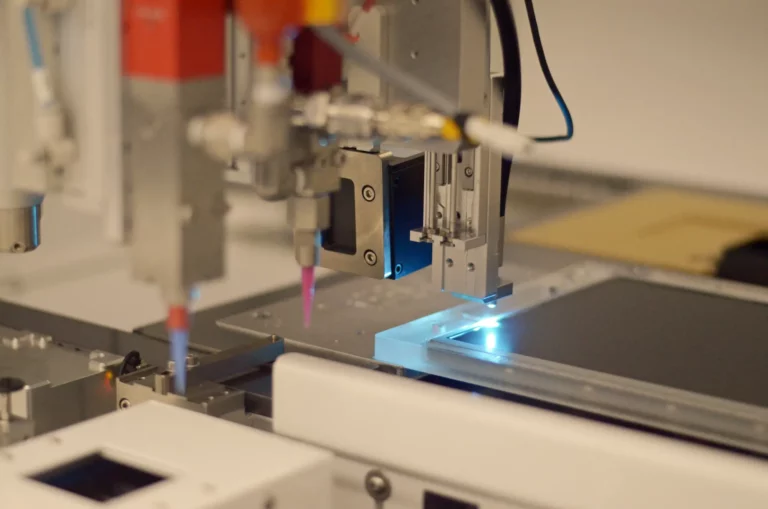

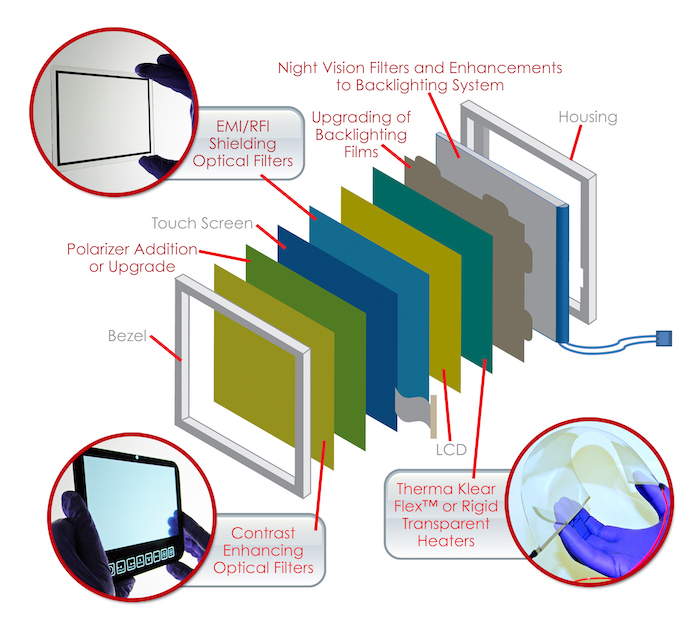

We leverage our expertise in optical filter design and production to enhance touchscreens and displays in our clean rooms with our IMO-bond™ laminations, creating custom touchscreen and display solutions and adding performance enhancing features including:

Low Temperature Operations

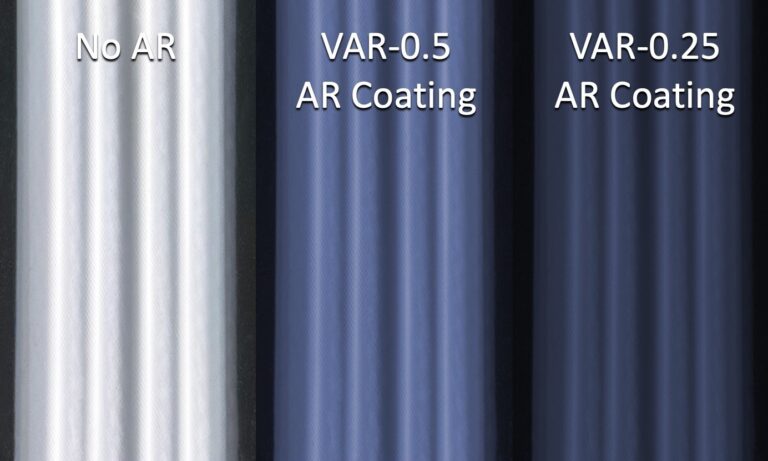

- Thin film deposited antireflective coatings for UV, visible, IR

- Photopic reflection <0.1%

- Low diffuse and specular reflection coatings

- Index match conductive AR coatings

- Antireflective

- Antiglare cover glass

- Glass and acrylic polarized filters

- Bandpass filters for monochrome displays

- Triple-notch RGB filters

- Glass, acrylic, and polymer substrates

- Antireflective and antiglare coatings

- Polarized colored bandpass filters for contrast enhancement

- IMO-bond™ index-matched optical bonding, UV cured, silicone, dry bonding systems

- Custom chemically strengthened AR glass, heaters, EMI/RFI filters

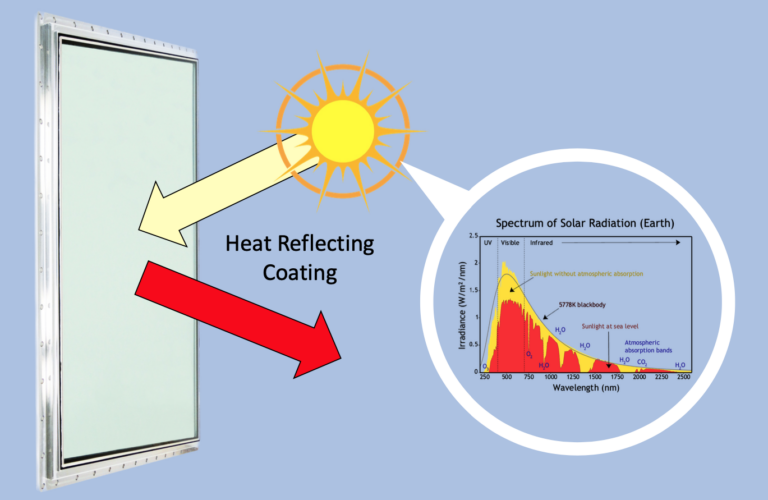

- Coatings for NIR/IR blocking, Thermal load rejection coatings

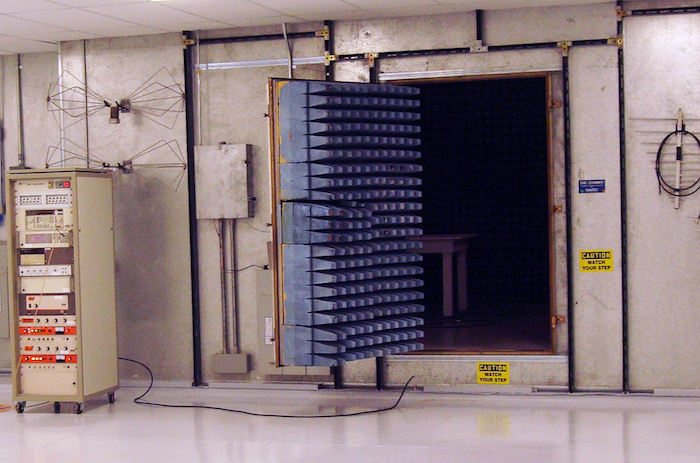

- EMI/RFI shielding

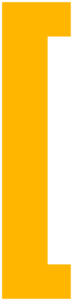

Glass Front Resistive and PCAP Touchscreens

- Rugged, scratch resistant front surface

- AR, AG coatings

- Reduces microbial contamination on surfaces

- Active silver ions reduce bacterial activity

- Gloss or antiglare surface finishes

Ruggedization

- Impact resistant chemically strengthened glass

- Optically bonded AR coverglass

- Flexible or rigid transparent heaters

EZKlean™ Coatings

- Hydrophobic coatings reduce surface energy

- Resists fingerprinting

Integrations & Enhancements

- Rugged sunlight readable displays with chemically strengthened, AR/EMI coated cover glass that is optically bonded to a high bright LCD

- Touchscreen customization with AR coating on the front and a dielectrically enhanced conductive coating (i.e., conductive AR) or optical mesh for EMI shielding on the rear.

- Low temperature displays customized with ThermaKlear™ transparent heaters

- High temperature enhancement – HeatShield™ coatings on cover glass integrated into touchscreen

- Full component integration of EMI/RFI shielding filter into custom touchscreen with chemically strengthened glass, AR glass or film front, optically bonded to a high-brighted LCD, fully integrated into the housing to meet both EMI/RFI and environmental compliance (e.g., shock and vibration, temperature & humidity)

Using our Class 1,000 and 10,000 ESD-compliant clean rooms, Dontech integrates our specially designed optical components into LCDs and touchscreens. The touchscreen technologies we perform enhancements to include the following:

These are most the widely used due to cost, reliability, and simple pressure activation. Typically constructed using layers of conductive polyester film and glass, they require activation pressure to make physical contact between the conductive layers to generate an X-Y axis point. Inherent internal reflections may reduce high ambient light performance. Common configurations include 4-, 5-, and 8-wire touchscreen constructions. Multi-touch and gesture recognition capabilities are now available. Sunlight readability can be improved in LCD applications via antireflective coatings and layers of circular polarizers and a ¼ wave retarder to minimize internal reflections.

PCAP has become increasingly popular due to its very high resolution, ease of multi-touch and low internal reflections. Projected capacitive technology relies on a capacitance change that occurs when touching near or on the sensor surface. A conductive grid is patterned on the glass surface and forms an X-Y array. Applying voltage to the array creates a grid of capacitors. The array is connected to a controller that converts analog to digital signals and locates the exact contact point. Most users are comfortable with this technology because it is used on many consumer phones and tablets.

SAW technology uses ultrasonic waves to register the touch location. As a portion of the wave is absorbed by the touch, it sends a signal to the controller. Because it requires very low activation pressure, a SAW touchscreen can be sensitive to surface contamination or damage. This technology is not typically selected for high-reliability applications.

These touchscreens operate using an array of near-infrared light emitting diodes (LEDs) and photo-sensors to locate X and Y coordinates. The touch location is identified by the interruption of the IR beam. IR touchscreens provide very good optical clarity and can accommodate very large displays. Resolution is dependent on spacing of the IR sensors; false activation can occur due to surface contamination. High ambient light that produces IR radiation may reduce the sensitivity of the IR sensors and, therefore, decrease touchscreen functionality.

This is a relatively new technology that uses optical sensors on the corners of the touch screen and infrared backlights to create a two-dimensional field. Touches are detected as shadows which are used to interpolate the location of the field disruption. OI technology is scalable to large display sizes.